Insider Tips to make manufacturing small runs more cost effective

First, some facts about manufacturing

Commercial manufacturing is geared towards large quantity runs because commercial presses, inks, large rolls of papers, dies, and films are required to create the finished product. All of these set-ups costs are required for the beautiful, professional finished products that you see on shelves but make small quantity manufacturing runs cost prohibitive.

Tip #1 – 500 UNITS is almost the same cost as 300 units

300 Quantity is the min order for packaging or discs and is the most expensive per unit cost.

500 Quantity will actually end up being almost the same total cost as 300 so do yourself a favor, and explore 500 qty instead. The production costs for 300 and 500 are about the same (it’s 97% set up costs), shipping costs make up the small remainder of the difference.

Tip #2 – 1000 UNITS is the sweet spot for starting decent per unit costs

If you are looking for good per unit costs, we’d recommend at least 1000 units. A run of that size offsets most of the set up costs. However making 1000 of an item has a much higher per unit than a large, mass outlet retail item. That really cool item that you see in stores retailing at $19.99, is probably made at 25,000 units or more, so be realistic in your retail goals.

Getting creative to be cost effective

Ok, so let’s say you can’t do a traditional run of 500 or 1000. Knowing that you’ll need to order at least 300 of something, and you are in for a cost of several thousand dollars, what are creative ways to get around the 300 of the same item requirement or make the run more cost effective?

Tip #3 – Gang Runs

Share production costs & manufacturing costs by running multiple items together. If you have several small runs of the same packaging that we can manufacture together and ship together, you can reap some significant savings. Try to use the same paper stock, inks (cmyk or pantones), and shipping location to reap the most benefits. Some successful examples based on past orders include:

- Record labels – two 250 qty runs of cds in BlueNote LPs; two different artists/runs but same type of packaging, cmyk ink, shipped to distribution center

- Church/Educational – releasing English Version and Spanish Version of the same product (300qty x 2 sets) with similar production paper/packaging/ink and shipping = savings.

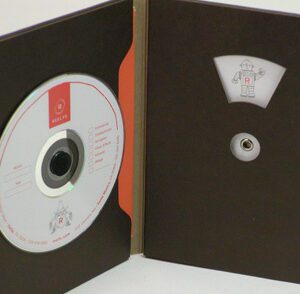

- Company – 10 dvds in jackets, same packaging, same pantone inks (red and white)

- Small artist – releases a limited edition with special effects and slipcase, and regular edition without the bells & whistles.

- Individual – runs one main title, and tacks on a separate slipcase-only order for a different title. This shares the shipping cost making the stand-alone slipcase order affordable.

Tip #4 – Generic Artwork

Can you design your packaging so that it works for multiple titles?

- Real Estate company – 500 Portfolio Folders with their brand on it that they can send to multiple clients. Discs and literature inside are customized.

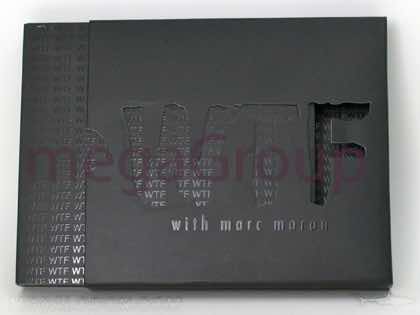

- Record Label – 1000 Black Boxes to be used for small releases, customized with inexpensive bellybands printed locally in small quantities

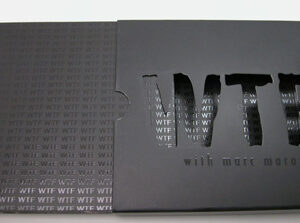

Tip #5 – Die Cuts to Showcase Inserts

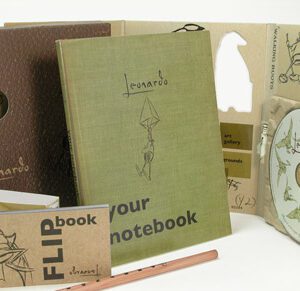

Create packaging with a die cut to showcase the underlying print. Your main packaging would be made in bulk (300/500 qty) and smaller runs of booklets, inserts, cards, photos, etc. would be used to personalize the item.

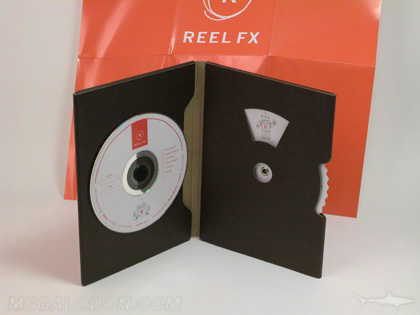

- Digipak/Jacket with a large die cut window in the front panel that showcases a booklet that fits inside. Your main packaging is generic, the booklet can change the title/front cover with each of your releases.

- Photographer uses a die cut window to showcase a photo.

- Slipcase die cut to show personalized item underneath.

- Company uses business cards to showcase the individual’s name. We’ve seen this work with film companies and advertising agencies and companies generating portfolios for specific clients.

Tip #6 – Small 1C Black Plate Changes

If you need to personalize the packaging with a title, name, or date change in black ink, and the rest of the packaging artwork is identical, you can do this without too much cost. Discs can also be serialized.

- Film company highlights different directors’ cuts. A 1C black name change personalizes the packaging.

- Serialized discs used for collector editions.