Adding custom die cuts to packaging is a complete game changer. In case no one has told you, you actually are *not* bound by part numbers or restricted by what clients before you have done. You can indeed forge your own way and make a mass manufactured commercial package that is entirely your design.

Custom Die Cuts – Definition & How They are Made

So what is a custom die cut? Dies are used to consistently cut the same packaging. In essence, a custom die is needed for every unique design. In the manufacturing world, we refer to this as a knife – it cuts the pattern. The blades are set up in a special, controlled fashion so that the packaging can be machine cut and precisely replicated. Fine, detailed designs require metal blades, others allow for plastic. Now you know, that’s how it’s done!

Die Cuts are used to create custom packaging and allow you to be very creative. They are frequently used for custom shapes, lettering cut outs, and shape knock outs. They are a one-time expense and relatively inexpensive, especially if the quantity is 1000 units or more.

Uses for Custom Die Cuts

What can you use a die cut to create? Ah….here is the fun. You can create just about anything you can imagine provided the pesky physics of the materials do not interfere.

Custom Die Cuts – Shapes

Let’s say that you want to create packaging that looks like a beautiful invitation, complete with custom envelope and a window cut out that shows the name of the invitee underneath.

Quite possible – the main packaging is mass made in the due cut shape and the individualization could be done with digital one-sheet inserts. You can use the same theme for photography or film reels.

Other fun examples include things such as spinny wheels, heart shaped packaging, rounded pockets, and images in end panels that form an image when put together.

Lettering

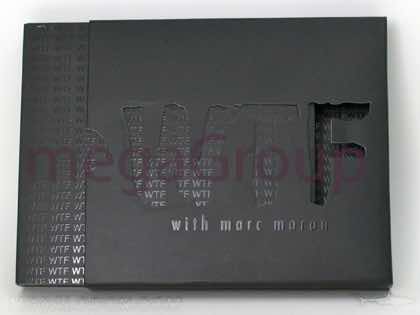

Lettering Cut Outs (aka Knock Outs) are super popular. Our two favorite examples are GOD and WTF. By cutting the letters you achieve a visual (and textile) logo that stands out, and may reveal something very fun underneath. Lettering is frequently done on slipcases which are somewhere between 15/16pt and 21pt stock thickness.

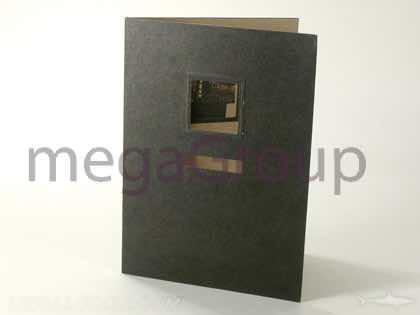

Windows

If you are looking for a larger area to showcase something underneath, a Window may be a good choice. Some of our favorite examples; a window framing a portrait, a hole with a cute character inside (I mean who doesn’t like this? More of this in the world please), a circle showcasing an empty chair where you apparently should be sitting. Feel free to squiggle too, shapes need not be geometric. We did a lovely violin cut out.

Vinyl Record Cut Outs

With the return of vinyl packaging, we now have an influx of vinyl dies. One of the most popular is the center cut out for vinyl records.

3D Pop Up Dies

How complex can we get? Origami level. We have a copyrighted pop-up pak that borders on origami folding. We actually have to apply a special wax for consistent opening. It took some time to work out the details. We love our creative clients, we really do. You all design the impossible, we try to find solutions to make it work.

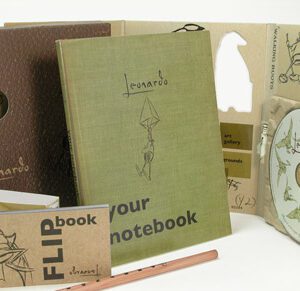

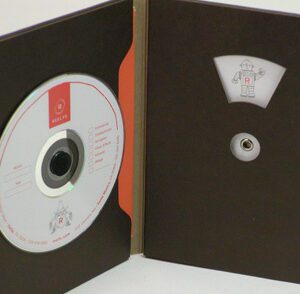

Retail Items

There are also a wonderful variety of practical applications (beyond the cute characters, which we feel strongly about). Die cuts can be used to hold retail items such as usb drives, charging cords, yo-yos or or super hero action figure toys, coins, pencils, art cards, business cards, or seed packets.

Combining Effects with Custom Die Cuts

Have fun combining special printing effects. Consider a spot gloss or embossed area under a cut out. Take a look at our Special Effects Pages to peruse some of the options, such as foil stamping, embossing or debossing, spot gloss, or metallic inks.

Art SetUp – Creating the Die Cut Area

To create a die cut, you will need to specify the area to be cut in a layer of your artwork. Designate a special color to represent the die cut.

Proofing

For proofing, we recommend that we make a hand made mockup so that the design details can be worked out. You could just view the die cut print out on a piece of paper and use your imagination or scissors and folding skills, but a mock up is probably worth the small expense of a few hundred (depending on complexity of course).

Schedule

Custom projects do require a little more time than previously done projects. As you might imagine, there are tweaks and adjustments that may need to be made along this newly forged path.