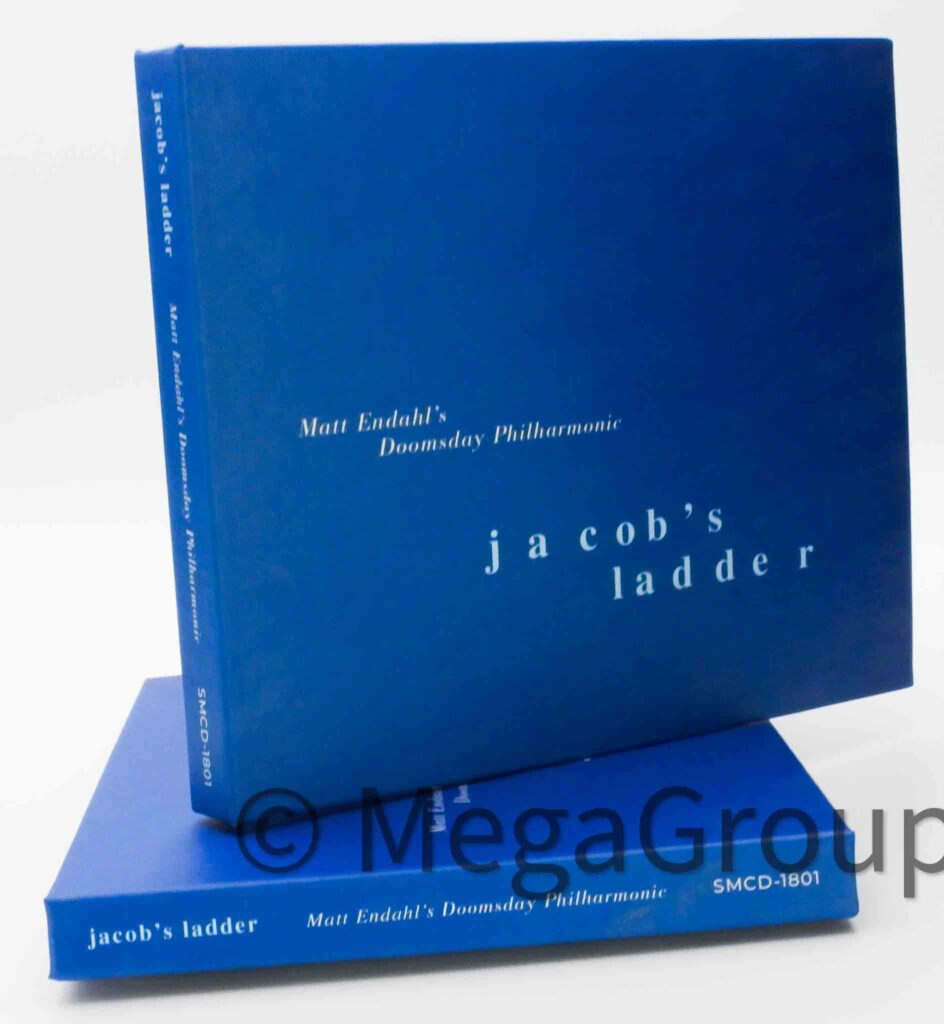

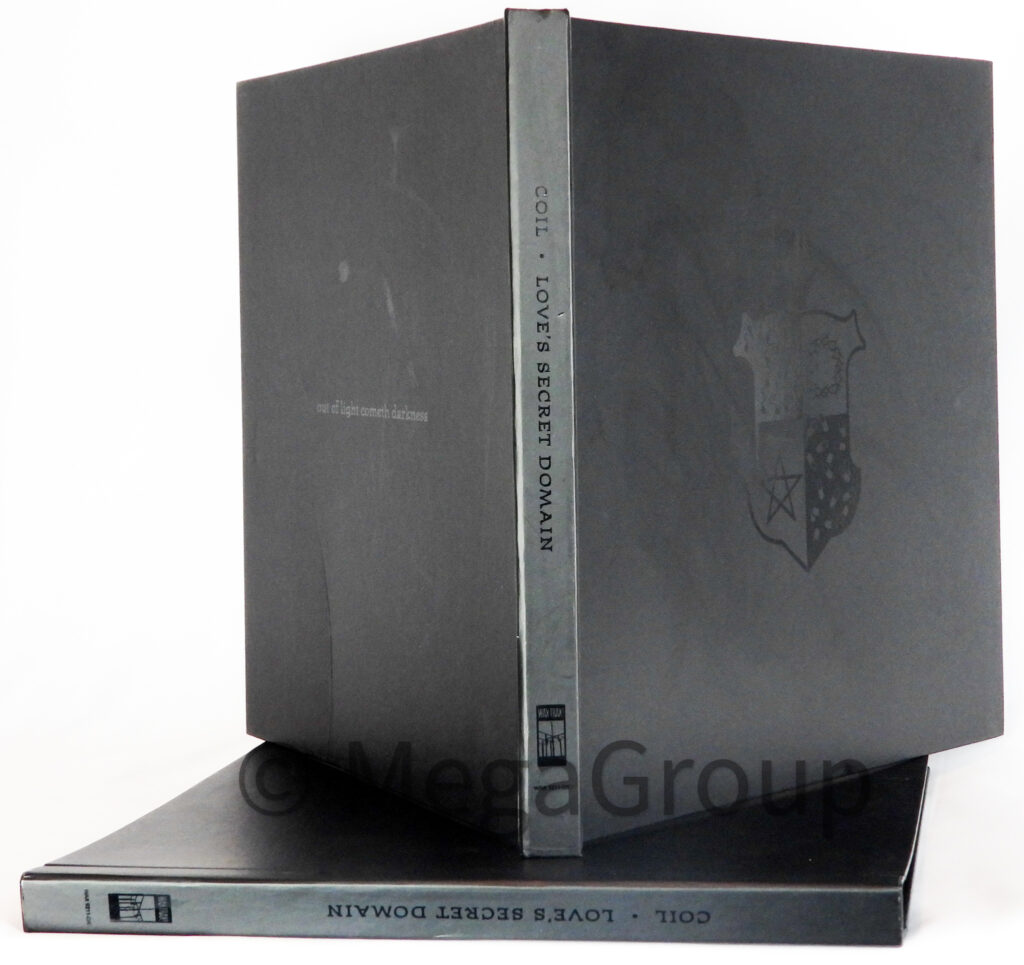

Rigid Chipboard Packaging – The Thickness You Want

What’s chipboard packaging? Chipboard is the behind the scenes material that makes thick, rigid packaging. We’ve all seen the finished products – beautifully wrapped, deluxe retail boxes for products, media, fancy hardcover books, rigid LPs. But you probably never peeled off the pretty wrapping to see the chipboard inside.

What is Chipboard Made of?

Inside these sturdy packages, is a strong material called chipboard. Chipboard is made of small wood fibers that are usually reclaimed waste product, mixed together with an epoxy resin to form a solid slab. This slab is used inside packaging products to provide rigidity. It brings the “hard” to Hard Cover Books. The material is generally grayish in color and is considered rather unattractive. But don’t worry…

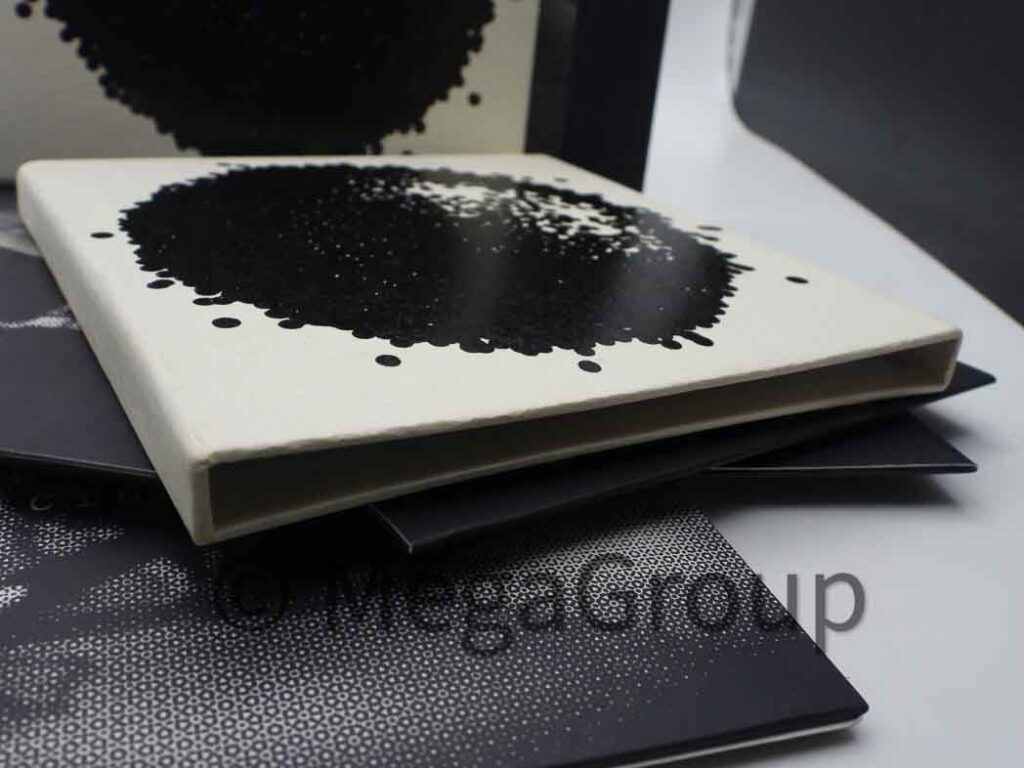

Chipboard Packaging Wrapping

The unattractive chipboard is not actually seen. It is covered up with either a printed paper, or a material such as linen or leather or fabric paper. Your final result, is a sturdy, rigid, beautifully wrapped package with the material of your choice. Choose from printed paper, linen, fabric paper, or leather wrapping.

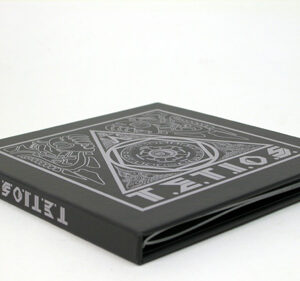

Paper Wrap

A piece of paper, about 120gsm in thickness, is printed on the press and then glued onto the chipboard. To seal it, a thin piece of plastic is heat sealed onto the paper, creating a lamination.

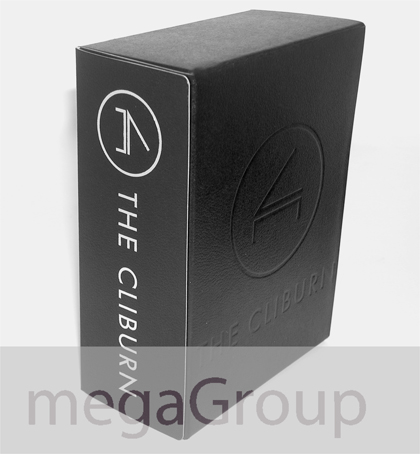

Linen Wrap

Linen fabric material can also be wrapped over chipboard. It is silkscreened with a simple design and glued onto the chipboard. This material can also be foil stamped. We also have a fabric paper that allows more complex designs.

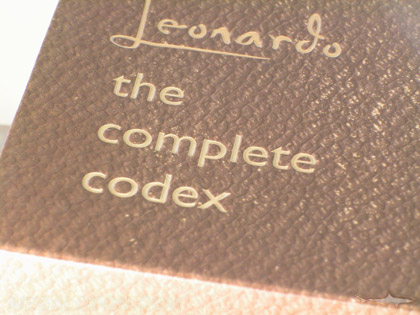

Leather Wrap

Our faux leather material is another fun option providing an old world look. Leather cannot be printed with ink but can be hot foil stamped or debossed for extra texture.

Examples of Chipboard Packaging

See also sister sites: cd-dvd-book-printing.com and vinyl-packaging.com